Energy Management — Canfor Pulp

Canfor Pulp’s modern kraft mills operate as large-scale biorefineries, allowing us to efficiently manufacture premium pulp products while producing clean energy. We use steam generated in our boilers to generate electricity and heat our operations, and export surplus power to the BC grid to sell to other users.

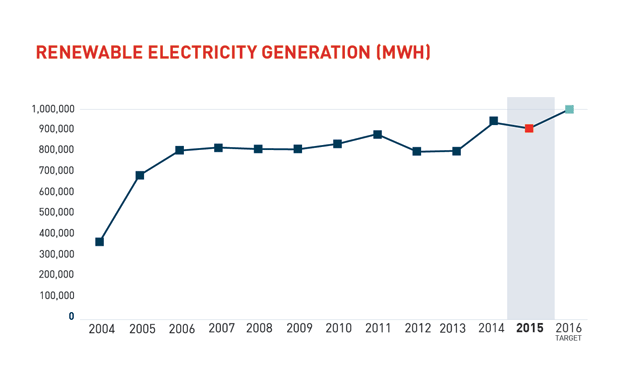

In 2015, we completed the 32-MW steam turbine at Intercontinental Pulp, which means the turbines at all three of our Prince George pulp mills are selling power. Canfor Pulp delivers renewable power through long-term agreements with BC Hydro under their Integrated Power Offer that encourages pulp and paper producers to invest in energy efficiency and biomass power generation. Canfor Pulp generated 910,993 MWh of renewable energy in 2015.

In 2015, FortisBC awarded Canfor Pulp its Efficiency in Action Award in the industrial sector for an upgrade at Prince George Pulp and Paper that significantly reduced our use of fossil fuels. In partnership with FortisBC, we upgraded the chain used in our rotary lime kiln to a more thermally efficient version, reducing our natural gas use by 67,000 gigajoules in the first 18 months alone.

We took an outage at the Intercon mill during the installation and commissioning of the new turbine. The energy systems at all three Prince George mills will be fully operating in 2016 so we should meet our 2016 production target of 1 million MWh/yr.

We took an outage at the Intercon mill during the installation and commissioning of the new turbine. The energy systems at all three Prince George mills will be fully operating in 2016 so we should meet our 2016 production target of 1 million MWh/yr.