Carbon Footprint

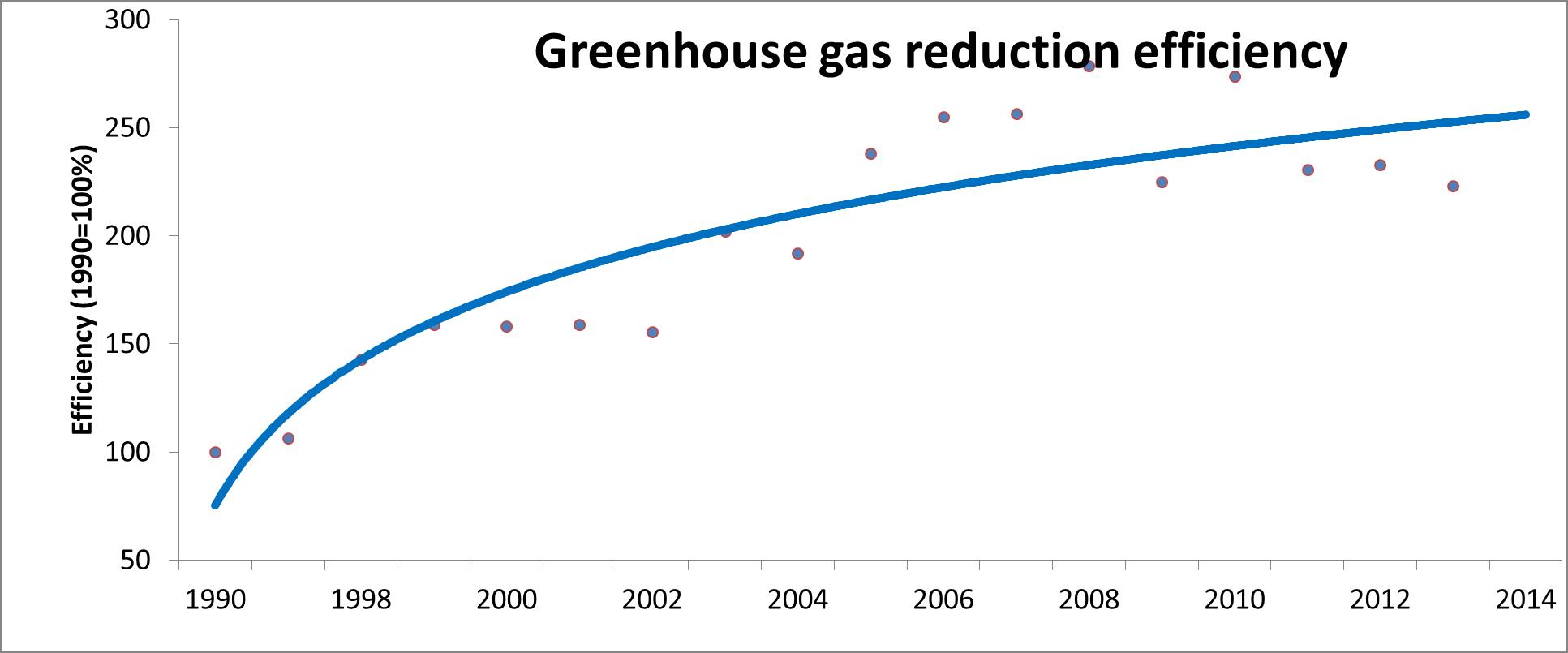

Canfor and Canfor Pulp continue to look for ways to combat climate change by improving our manufacturing processes, reducing our greenhouse gas emissions, and increasing our use of sustainable biomass for power and heating. Using biomass in place of fossil fuels reduces our operating costs, yielding economic as well as environmental benefits.

When our pellet plants at Chetwynd and Fort St. John reach full capacity in 2015, they will have a combined annual production capacity of 175,000 tonnes of wood pellets, and the Chetwynd project will displace 21,000 MWh of electricity consumption every year for 20 years.

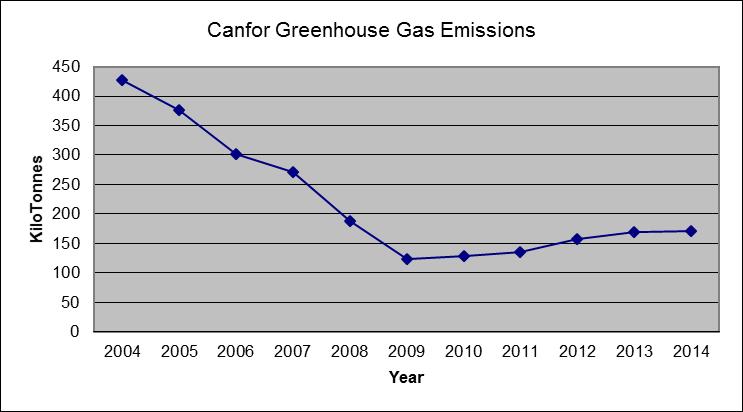

Greenhouse gas emissions increased marginally as they include a full year of operation of our Elko Sawmill.

The Elko biomass-fired thermal energy system, which started up in October 2014, will eliminate most of the natural gas usage at Elko and generate 10,000 to 12,000 t CO2e greenhouse gas emission reductions. Canfor and Canfor Pulp both sell carbon offset credits into the BC offset market, and Canfor sells credits into the Alberta carbon offset market.

Canfor Pulp’s recent investment in biomass boiler upgrades at its Northwood facility reduced greenhouse gas emissions by 67,000 tonnes CO2e in 2014.