Energy Management — Canfor Pulp

Our modern kraft mills operate as large-scale biorefineries, allowing us to efficiently manufacture premium pulp products while producing clean energy. We use steam generated in our boilers to generate electricity and heat our operations, and export surplus power to the British Columbia electricity network. As noted in the Innovation section, we continue to explore the potential to convert waste from kraft pulp mill production processes into a low-cost biocrude oil through our joint venture agreement with Licella Fibre Fuels.

Canfor Pulp continues to invest in energy efficiency and renewable energy generation. In 2017, we began a $65-million project to install a third turbine at Northwood, and a $40-million capital project to reduce the electrical and thermal energy required at the Taylor mill. These two projects will improve the cost competitiveness of the mills and reduce the environmental impact and will be fully operational early in 2019.

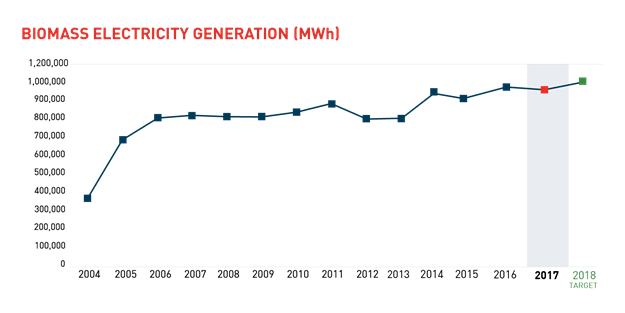

Canfor Pulp generated 951,347 MWh of power from our three Prince George mills in 2017, and expect to achieve our target of one million MWh/yr in 2018.

Canfor Pulp generated 951,347 MWh of power from our three Prince George mills in 2017, and expect to achieve our target of one million MWh/yr in 2018.