Carbon Footprint

Canfor and Canfor Pulp continue to look for ways to combat climate change by improving our manufacturing processes, regenerating forests, reducing our greenhouse gas emissions, and increasing our use of sustainable biomass for power and heating. Using biomass in place of fossil fuels reduces our operating costs, yielding economic as well as environmental benefits.

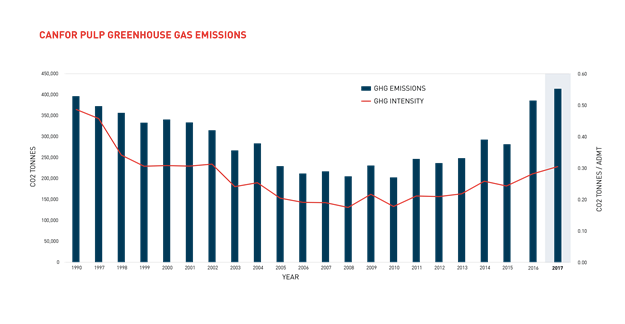

Our manufacturing plants have established goals to further reduce greenhouse gas emissions. We are investing in technologies that use biomass instead of fossil fuels and are adopting operating practices that increase overall energy efficiency. In 2017, we announced that our Taylor pulp mill will invest $40 million to modernize the pulping process – this will reduce greenhouse gas emissions by 25% and electrical energy by 10%.

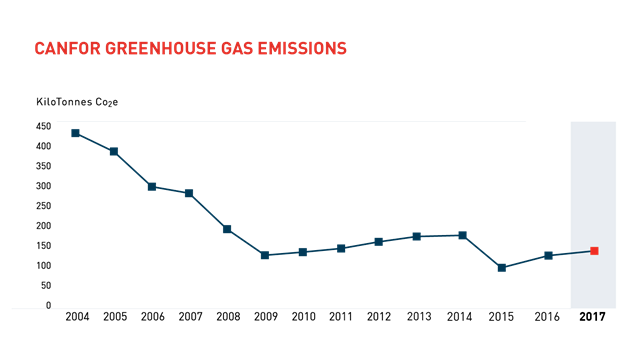

The moderate increase to Canfor’s greenhouse gas emissions resulted from increased production demands from diesel and natural gas. Propane use remains steady.

The greenhouse gas emissions for 2016 and 2017 include the Taylor Pulp Mill which was previously captured under Canfor’s GHG totals prior to this. Taylor Pulp adds 64,913 and 61,612 tonnes of CO2 for 2016 and 2017 respectively to the Canfor Pulp total. Canfor Pulp’s natural gas consumption in the boilers increased in 2016 and 2017. These mills have set goals for 2018 to increase biomass energy production to support our path to reducing our carbon footprint.