Energy Management — Canfor

Our energy management initiatives are saving 14,900 MWh annually thanks to the efforts of our energy manager and mill employees. That’s enough energy to power 1,040 homes each year.

In 2017, we focused on piloting an energy audit, which helped raise awareness about energy-saving opportunities at two divisions, achieving the goal for raising awareness that we set in 2016. At our Plateau mill, the audit identified ways to optimize equipment, leading to a reduction of 1,600 MWh annually. In 2018, we plan to roll out the audit process to three more divisions and develop strategic capital projects to reduce energy consumption.

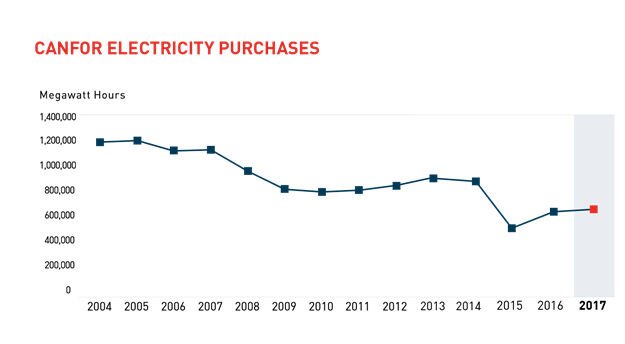

We have a standing target to reduce electricity per unit of production at our BC and Alberta sawmills by 10%. However, the industry is harvesting greener fibre, which is wetter and requires more energy to dry and process. Combined with a slight decrease in production relative to 2016, this led to an increase in energy per unit of production in 2017 compared with 2016. In 2017, we realized a 117.8 kWh/Mfbm intensity – 0.65% less than 118.5 kWh/Mfbm in our baseline year of 2011.

When considering all of our business, at our Chetwynd Pellet Facility, the organic rankine cycle (ORC) generator continued to ramp up in 2017, and is now operating at capacity consistently. The output in 2017 was 6,600 MWh above our baseline – enough to power 1,350 homes.

Canfor was among 32 customers recognized by CN under its EcoConnexions Partnership Program for their commitment to reducing carbon emissions and increasing energy efficiency. Canfor’s Mark Feldinger, Senior Vice President, Global Supply Chain for Canfor and Canfor Pulp, with Fiona Murray, CN’s VP of Industrial Products.

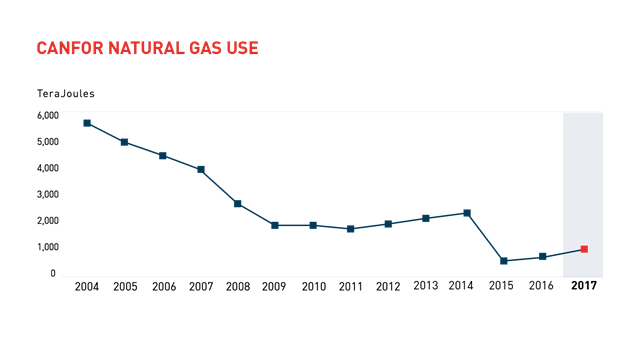

Natural gas purchases increased slightly at both our Canadian and US operations due to adverse weather and a shift to greener fibre, which requires more drying capacity and heat to dry.

Natural gas purchases increased slightly at both our Canadian and US operations due to adverse weather and a shift to greener fibre, which requires more drying capacity and heat to dry.

Improvements to electrical consumption resulted from: better utilization of the Canfor Energy North organic rankine cycle generator at the Chetwynd Pellet Plant, internal energy management activities, and the sale of the Canal Flats mill site that took place in mid-2017.

Improvements to electrical consumption resulted from: better utilization of the Canfor Energy North organic rankine cycle generator at the Chetwynd Pellet Plant, internal energy management activities, and the sale of the Canal Flats mill site that took place in mid-2017.